- #SIMATIC STEP 7 SIMULATION VERIFICATION#

- #SIMATIC STEP 7 SIMULATION SOFTWARE#

- #SIMATIC STEP 7 SIMULATION CODE#

The only thing that must be done from now is to activate the activation inputs and the sensing outputs. And with one command, your model got created automatically according to CAD assembly. With the couple of clicks, you can import that model in Simulink. Each body element is connected to its mate with joints that represent the degree of freedom. Here, you see the model of the robot in a CAD tool. And, therefore, most of the work to create a model of the plant is already done. Almost all companies in the industry throw their machines in CAD tools. But we see that, in most cases, the models already exist, just in a different development tool.Īnd this is the CAD tool. Of course, such a model doesn't fall from the sky. This allows plenty of tests, design iterations, and optimization on the complete system, or single component, without spending thousand of dollars in prototype, manufacturing, testbenches, traveling, and so on.

#SIMATIC STEP 7 SIMULATION CODE#

It becomes obvious, right away, that you can run your system without having manufactured one single mechanical part, connected one single wire, or transferred any line of code to a PLC. And the two inner are for the arm of the robot and for the gripper. The outer state machines are for the conveyor belts.

#SIMATIC STEP 7 SIMULATION SOFTWARE#

The algorithm of that control software is divided in four single state machines that interact with each other via events.

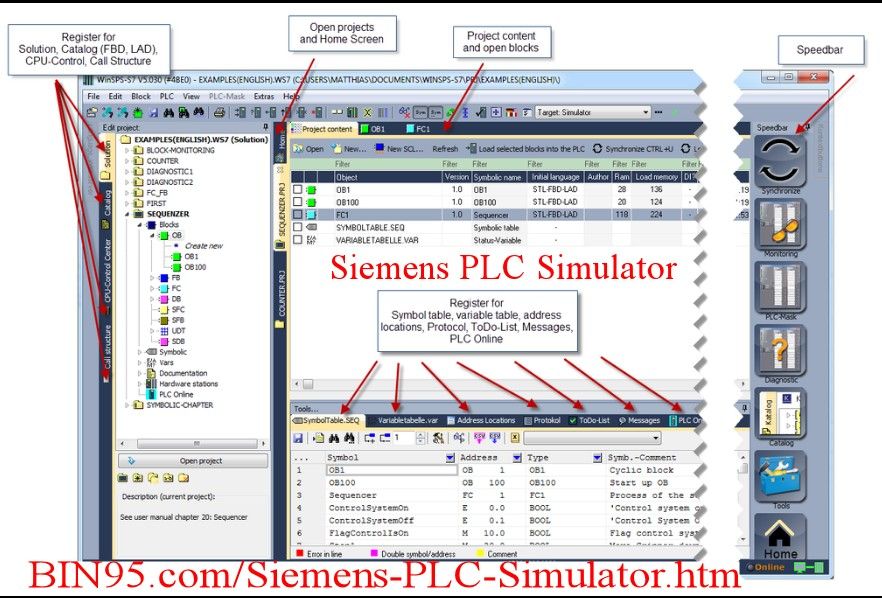

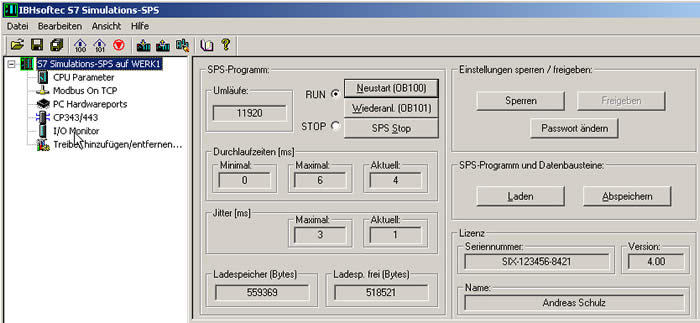

And in the second window, you also see the animation of the state chart that controls the robot arm. In an animation window, you see how the plant part behaves. The first thing you can do with this model is to simulate it in Simulink in the model-in-loop simulation. In this model, you can see right clearly a closed-loop system that has a plant part that is represented as a robot arm- or, more general, as a mechanical assembly- and the control part that is in the front that controls the motion of the mechanical assembly. After that, Felipe will take over and speak about the code generation using the SIMATIC Target 1500S for Simulink, followed by the integration into a STEP 7 TIA Portal project.įinally, we will run the co-simulation between the Digital Twin and Simulink and the control algorithm on the simulated Siemens PLC, the PLCSIM Advanced. Then, we will see how controller logic can be modeled in Simulink to run a closed-loop desktop simulation. First, I will show you a quick and easy way to create simulation models out of your CAD drawings. And I am responsible for automation and virtual commissioning topics. Felipe Ravazzi, who will later take over the topic of code generation, integration, and co-simulation.įelipe, maybe you can give a brief introduction on your own? And for the second part, we have support from Siemens by Mr. Today, I will do the first part of this video covering the modeling path in a Simulink environment. And I am an application engineer at The MathWorks in Germany. Hello, and welcome to this video on virtual commissioning with Siemens SIMATIC Target 1500S for Simulink.

Finally, watch as virtual commissioning is performed using the SIMATIC S7-PLCSIM Advanced simulated controller. Then see how the application is integrated into the TIA Portal project using automatic code generation and the Siemens ® SIMATIC ® Target 1500S™ for Simulink ®. Learn how you can create a digital twin of your machine and simulate it with the control algorithm. This approach reduces costs, ensures high product quality, and speeds up commissioning. In the simulation model, the interaction between mechanics, machine software, and the product to be manufactured can be tested, optimized, and verified in various scenarios before the physical machine is available.

#SIMATIC STEP 7 SIMULATION VERIFICATION#

Virtual commissioning enables early testing and verification of the software using a digital model of the machine. The late availability of the physical machine or plant makes testing the machine software more difficult. Due to the increasing share of software in modern production machines and systems, the risk of not being able to keep costs, project duration, and quality during on-site commissioning is increasing.

0 kommentar(er)

0 kommentar(er)